Discover the Unparalleled Excellence of Superfine Minerals:

A Complete Tale of Mining and Market!

TALC FOR PLASTICS USE:

The Hidden Hero of Plastics: How Talc Enhances Performance and Prevents Problems

Talc plays a surprisingly diverse and crucial role in the plastic industry, influencing everything from final product properties to processing efficiency. Here's a closer look at its superpowers:

Boosting Mechanical Properties:

Think of talc as a microscopic gym trainer for your plastic. It strengthens and stiffens the material, improving resistance to bending, cracking, and impact. This makes it ideal for applications like automotive parts, construction materials, and even toys that need to withstand some rough play.

Dimensional Stability: Imagine baking a cake that keeps expanding after it leaves the oven. Not ideal! Talc helps plastics maintain their desired shape and size after processing, even in high temperatures or humid environments. This ensures reliable performance and consistent product quality.

Mastering the Stiffer-to-Impact Balance:

Balancing stiffness with impact resistance is a delicate dance. Talc allows you to achieve both, creating plastics that are strong yet flexible enough to withstand knocks and bumps without shattering. This is crucial for products like packaging materials and sports equipment.

- Teamwork with Other Additives:

Talc doesn't work alone. It plays well with other additives like stabilizers and lubricants, forming a dream team to extend the life of the plastic compound and optimize processing. This allows manufacturers to create high-quality products more efficiently.

- Taming Sticky Situations: Rubber chips and other sticky materials in plastic blends can turn into a gooey mess if not managed properly. Talc's high surface area and water-repellent nature come to the rescue here. It coats these sticky particles, improving flowability and preventing them from clumping together. This ensures smooth processing and consistent product quality.

- Moisture Shield for Hygroscopic Components:

Some plastic components readily absorb moisture, which can compromise their properties. Talc acts as a moisture shield, protecting them from the environment and ensuring long-lasting performance. This is particularly important for outdoor applications like building materials.

Preventing Summertime Clumping:

High temperatures can cause polymer chips, especially those with high elastomer content, to clump together during storage. Talc comes to the rescue again, preventing re-agglomeration and ensuring smooth handling and processing even in harsh summer conditions.

The Secret Weapon for Smooth-Flowing Polymer Granules:

Say goodbye to sticky, clumpy polymer granules that disrupt your production process and compromise the quality of your final product. Superfine Minerals as a range of talc products specially formulated to conquer these challenges and ensure smooth, efficient granule handling.

Why Superfine Minerals Talc?

- Hydrophobic Hero: Superfine Minerals talc's unique hydrophobic character acts like a microscopic raincoat, repelling moisture and preventing granules from sticking together. This means no more clumps or blockages in your processing equipment.

- High Surface Superstar: With its high specific surface area, Superfine Minerals talc efficiently coats each granule, creating a smooth, slippery layer that promotes effortless flowability. Imagine your granules gliding effortlessly through your machinery, boosting your production speed and efficiency.

- Partitioning Prowess: Superfine Minerals talc excels at partitioning sticky additives and fillers within your polymer blend. This prevents interactions and ensures consistent product quality, color, and performance.

The Superfine Minerals Difference:

- Variety of grades: Choose the perfect talc particle size and surface treatment to match your specific needs and polymer type.

- Enhanced processing: Experience smoother flow, reduced waste, and improved equipment uptime with Superfine Minerals talc.

- Superior product quality: Create high-quality, consistent polymer products with excellent appearance and performance.

Ready to unlock the power of Superfine Mineral's talc?

Talc is not merely a filler in the plastic industry. It's a versatile hero, quietly enhancing performance, solving processing challenges, and ensuring the quality and reliability of countless plastic products we use every day. So, the next time you pick up a sturdy plastic container or admire a well-built car bumper, remember the invisible hand of talc working behind the scenes.

Contact us today to discuss your specific polymer granule partitioning challenges and discover how Superfine Minerals talc can help you achieve smooth, efficient production and superior product quality.

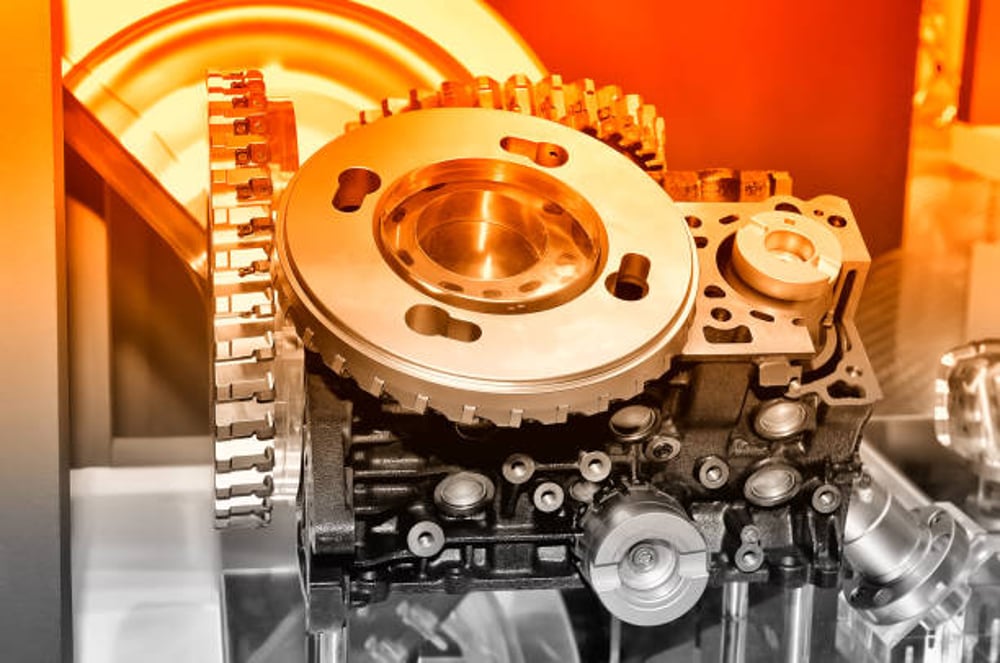

TALC FOR AUTOMOTIVE USE:

TALC IS HIGHLY FAVOURED IN A WIDE RANGE OF AUTOMOTIVE APPLICATIONS

Talc is an important mineral used in a variety of industrial applications. Here are some of the specific uses of talc in automotive applications:

- Talc is a good insulator: It has a low coefficient of friction, making it ideal for use in automotive applications.

- Talc is used in brake linings and pads: It helps to reduce noise and wear, and it also improves the effectiveness of the brakes.

- Talc is used in clutch facings: It helps to reduce wear and tear, and it also improves the performance of the clutch.

- Talc is used in gaskets and seals: It helps to prevent leaks and improve the sealing performance of gaskets and seals.

- Talc is used in plastics: It helps to improve the strength, stiffness, and dimensional stability of plastics.

- Talc is used in coatings: It helps to improve the appearance, durability, and corrosion resistance of coatings.

In addition to these specific uses, talc is also used in a variety of other automotive applications, such as:

- Lubricants

- Dusting agents

- Heat sinks

- Electrical insulators.

Its properties make it an ideal material for many different uses, and it is an important component of many automotive parts. Here are some of the benefits of using talc in automotive applications:

- Improved performance

- Reduced wear and tear

- Extended service life

- Reduced noise

Improved sealing

- Enhanced corrosion resistance

TALC FOR RUBBER USE:

Talc is a versatile mineral with a wide range of applications, including as a modifier for elastomers. Its platy structure and organophilicity make it an effective reinforcing agent, enhancing the rigidity and barrier properties of elastomers.

Additionally, talc's high specific surface area makes it a valuable dusting and partitioning agent for sticky compounds. This property helps to improve handling and prevent agglomeration.

Here're more detailed explanation of the key points:

- Platy structure: Talc's platy structure, which resembles thin sheets, allows it to align itself with the polymer chains in elastomers. This alignment enhances the transfer of stress from the polymer chains to the talc particles, resulting in improved rigidity.

- Organophilicity: Talc's organophilicity, or affinity for organic compounds, makes it easier for it to disperse in elastomers. This dispersion improves the interaction between the talc particles and the polymer chains, further enhancing the reinforcing effect.

- High specific surface area: Talc's high specific surface area, which is the amount of surface area per unit mass, makes it an effective dusting and partitioning agent. This property allows talc to absorb moisture and oil from sticky compounds, reducing their stickiness and making them easier to handle.

Additionally, talc's high surface area helps to prevent agglomeration, or the clumping together of particles, in sticky compounds. Overall, talc's unique properties make it a valuable modifier for elastomers and a versatile dusting and partitioning agent.

TALC FOR BUILDING PRODUCTS:

Self-leveling compounds and screeds:

- Creating a Flawless Floor: Self-leveling compounds and screeds are essential tools for achieving smooth, durable floors in almost any construction project. They excel at smoothing out uneven surfaces in preparation for a variety of final floor coverings, including carpet, tile, parquet, and vinyl.

- The Power of Superfine Minerals Talc: By incorporating specially chosen talc products from the Superfine Minerals portfolio, these compounds and screeds can be further enhanced.

Superfine Minerals talc offers several key benefits:

- Improved Flow: The talc's properties promote easier flowing of the compound, ensuring a more even application.

- Reduced Settling: Superfine Minerals talc combats the issue of clumping (sedimentation) in the filler, leading to a more consistent product.

- Enhanced Flexibility and Strength: The talc contributes to a material that's both flexible and possesses good compressive strength, making it more resistant to cracking and damage.

Wall fillers & jointing compounds:

Talc improves wall repairs:

Adding functional fillers like talc to wall fillers and joint compounds enhances several key properties. The Superfine Minerals talc range is specifically formulated to provide the right balance of:

- Flake shape (lamellarity)

- Particle size distribution

- Oil absorption capacity

-Resistance to cracking

- Smoothing of uneven surfaces

- Adhesion

- Sandability

These properties make Superfine Minerals talc ideal for use with gypsum boards before final painting.

Cost-effective option:

The Superfine Minerals talc range includes special white grades that allow for a single, cost-effective coat that can even serve as the final decorative finish.

TALC FOR PHARMACEUTICAL USE:

Superfine Minerals offers a comprehensive line of pharmaceutical-grade talc products meeting the strictest purity standards and adhering fully to major pharmacopoeias. These talc ingredients are prized for their inert and safe properties, making them ideal for use in pharmaceutical preparations.

- Focus on safety: Superfine Minerals pharmaceutical-grade talc prioritizes safety and purity, adhering to pharmacopoeial standards for use in sensitive applications like pharmaceuticals.

- Focus on specific applications: From tablets to capsules, Superfine Mineral's pharmaceutical-grade talc offers the ideal inert and safe ingredient for various pharmaceutical formulations."

TALC FOR HUMAN FOOD:

Superfine Mineral's food-grade talc is ideally suited as a filler for chewing gum. Its natural properties, including safety, inertness, plate-like structure, lubricating qualities, and water repellency, make it a perfect choice. Superfine Mineral's talc acts as an anti-caking agent, preventing other ingredients from clumping together. Furthermore, it complies with the FCC Standards for safe use in food applications.

TALC FOR COSMETICS:

Superfine Mineral's cosmetic-grade talc leverages its unique properties of water repellency (hydrophobicity) and plate-like structure (lamellarity) to excel in various cosmetic applications. Our talc acts as a mattifying agent in face powders and makeup, effectively reducing shine. Additionally, it functions as a thickening agent in liquid preparations, enhancing consistency for various cosmetic uses.

TALC FOR AGRICULTURAL USE:

- Animal Feed: Talc's unique properties, including its chemical inertness, hydrophobicity, and lamellar shape, make it a valuable addition to animal feed. It prevents clumping in sticky products and lubricates dies, ensuring efficient feed production and animal consumption which serves as an effective carrier in feed premixes.

- Compounds for Agriculture: Thanks to its high lamellarity and hydrophobicity, talc shines as a versatile agricultural formulation agent. It plays a dual role, acting as a carrier for herbicides, fungicides, insecticides, and fertilizers while serving as a cost-effective filler. And, to top it off, talc helps active ingredients stay on target during their action.

- Customer Support:

Our team thrives on helping customers achieve their goals by meticulously matching the ideal talc grades to their specific applications.

TALC FOR PAPERMAKING:

A Multi-Tool Mineral for Enhancing Paper Properties

In a nutshell

Industrial minerals like talc are often used to improve paper quality. Talc's unique properties, like its layered structure and water-repelling nature, make it a versatile solution for various paper needs.

Benefits of Talc for papermaking

- Pitch control: Talc prevents sticky impurities in paper pulp from clumping, improving papermaking and recycling processes. This avoids the need for harsh chemicals and keeps wastewater clean.

- Smoother, stronger paper: Talc's softness and layered structure enhance paper smoothness and durability, reducing scuffing during printing and making it ideal for delicate applications.

- Enhanced barrier properties: Talc's water-repellency makes paperboard more resistant to moisture, perfect for food packaging and other sensitive uses.

- Improved paper feel: Talc fillers reduce paper porosity, making it denser and smoother to the touch.

Different talc grades cater to specific requirements, ensuring optimal performance.

TALC FOR PAINTS & COATING:

- Made for Demanding Environments: These paints offer superior protection for various surfaces like metal, wood, and plastic, even in harsh conditions. From cars and boats to furniture, toys, and general applications, these paints provide a versatile solution.

- Sustainable Innovation: Growing environmental and health concerns have driven the development of eco-friendly coating systems.

- Key Ingredient: With its natural water-repellent properties, stability, and layered structure, Superfine Minerals Talc empowers manufacturers to meet the latest performance standards in sustainable coatings.

Breakdown of the key points

- Importance of Substrate Protection: Protecting materials like metal, wood, and plastic is crucial for economic (saves replacement costs), environmental (reduces waste), and safety reasons (prevents corrosion, etc.).

- Balancing Performance and Cost: Manufacturers need to select appropriate ingredients that deliver the desired protection while being commercially viable.

- Talc as a Functional Filler: Due to its natural properties like platy structure (improves adhesion), chemical inertness (doesn't react with other ingredients), and hydrophobicity (repels water), talc is a valuable filler for industrial coatings.

- Superfine Mineral's Talc Solutions: We offer a wide variety of talc grades, catering to diverse needs of paint and coating manufacturers. Some specific varieties include very pure talc, talc chlorite, and talc magnesite.

Overall, Superfine Mineral's talc is a versatile and effective solution for industrial coatings that prioritize substrate protection.